Tools: Level 2

Basic overhaul of your own saxophone (minor mechanical work)

These are the tools (in addition to all of the tools and supplies from Level One) that you can expect to use if you are going to perform a disassembly, cleaning, and full repad/basic overhaul of your own saxophone(s). The cost represented here is about $2000-4000, depending on how complete you make your set (one parallel plier vs. a selection of 5 different ones, for instance), bringing the total investment so far including level 1 tools to over $3000 at a minimum.

The skills necessary to use these tools well have become much more complex and represent a huge time investment relative to the more quickly learned skills of Level 1. At this point, you are endeavoring to become a professional and/or just have a major, possibly divorce-initiating passion for saxophone repair.

All tool companies mentioned below can be found in the links section.

Photos enlarge when clicked.

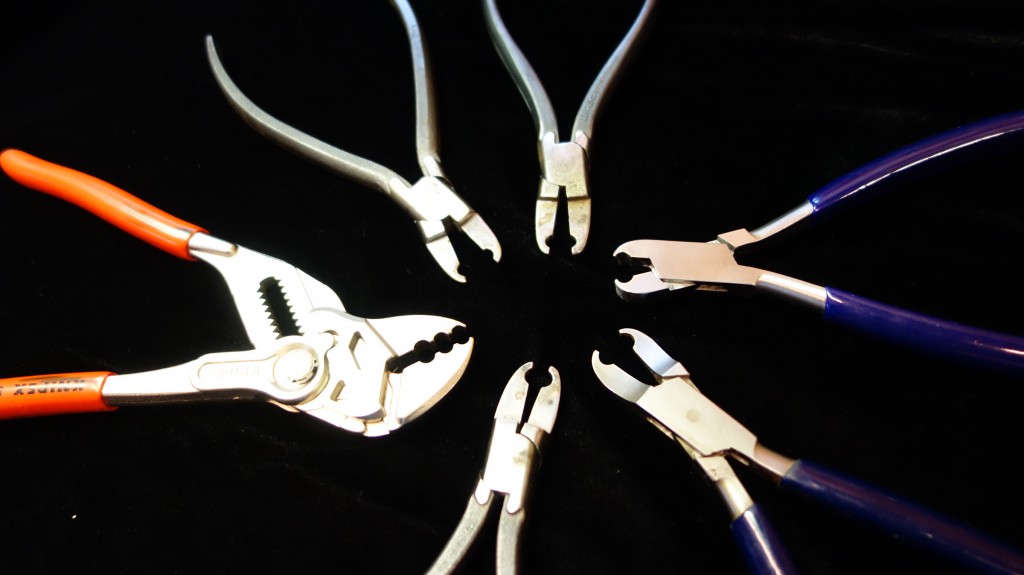

Spring installation pliers

Three jawed pliers used for pressing springs into posts, or for removing springs from posts that have been snipped or broken off near (but not inside) the post. The best of these come from Allied Supply.

Spring removal pliers

Two types, both of which I find useful. The fat jawed one lets you grab a spring and push or pull it through a post, the split jawed one helps push the stubs through the post when they break off at the post. The fat one is available at Ferree’s, the split jaw one pictured is no longer made but there are similar pliers available from Ferree’s and Allied and MusicMedic and probably elsewhere as well.

Parallel jaw pliers

Pliers with jaws that move parallel to each other throughout their range of motion, available in different sizes and with different jaw materials. Used for holding objects firmly with direct pressure, like bending a key arm. Available with soft jaws in plastic or brass, but I prefer regular hard steel jaws with paper or super thin cork on the jaws to keep from marring the held object when needed. Suppliers include MusicMedic, Ferree’s Tools, Allied Supply, and many others. I have several different versions, but I don’t think I could live without the ones made by Knipex (available on Amazon and elsewhere). Its good to have several pairs so you can hold with one pair and bend with another, and you’ll eventually want several sizes of jaw.

Spring bending pliers

These help to put bends in flat springs so they sit nicely in their cradles and also to help put a bend in needle springs. Requires a bit of finesse to get right. You can also do the job with your fingers and some finesse with needle springs, or some flat jaw pliers and some finesse for flat springs.

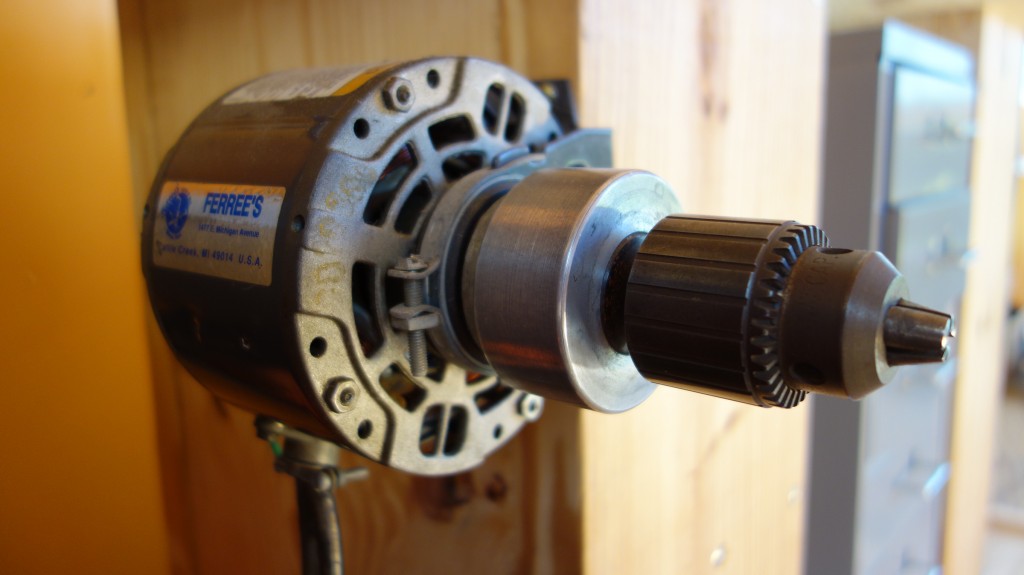

Bench Motor

Expensive, but necessary. Basically a nice electric motor with a nice and accurate chuck, sturdy spindle and a through hole. The ones made specifically for the trade are what you want. You can build one yourself, but unless you’ve got a lot more time than money you might be dissatisfied with the outcome. I have used one from Ferree’s going on 10 years now. Also available from Allied Supply and Votaw Tool has a super fancy one that is basically a Sherline lathe headstock with a variable speed control and keyless chuck. I personally also use an old Unimat DB200 micro-lathe as a secondary bench motor with collets to avoid marring hinge rods, but that is definitely overkill for most people.

Swedging pliers

I’ve got a ton of these, photo shows some of them. The more different widths, diameters, and designs you’ve got the easier it will be to deal with the many variations on the job of swedging you’ll come across. You want a close fit to the hinge tube you are swedging to avoid marring the key. I use ones from Allied, Ferree’s, and MusicMedic. The ones made from a Knipex parallel plier available at MusicMedic are particularly powerful, so use with extra care. Jaws must be symmetrical, aligned, and highly polished. If your set arrives and they are not, return them.

Lapping Compound

You’ll want a few different grits. I use the fine most often, medium and super fine have their uses. You will use very little of this. The stuff we use is way, way, waaaay finer than what you might have used if you work on cars or motorcycles and have lapped valves before. You will need to get the stuff made specifically for band instrument repair, which is available at Ferree’s, Allied, Kraus, Votaw, MusicMedic, JL Smith, and elsewhere.

Post swedging pliers

Getting the rod snug in the posts is a huge part of getting decent key fit, and so far the best tool for quickly accomplishing this is the post swedging plier from MusicMedic. Be careful though! Definitely a tool that requires a lot of finesse, and you will want to practice extensively on a junker first.

Cleaning brushes

Horsehair brushes are the way to go. You’ll want several different shapes and sizes, from a toothbrush on up. The main thing is you want the bristles to be softer than lacquer.

Cleaning area

You’ll need a large plastic or rubber basin (enamel/porcelain/metal will damage the instrument), a source of water, good lighting, and good drainage.

Cleaning soaps and solutions

I like Dr. Bronners “Sal’s Suds” as my main washing soap, with diluted Simple Green in a spray bottle. For plated instruments, you can also use diluted ZEP citrus cleaner. Whatever you use, test it out first!

Polishing materials (for silver or gold)

I use the polishing cloth available from Allied Supply. It comes in a long roll, and it is easily torn into strips. Its treated with a polishing powder, so use with ventilation. It polishes pretty well, but leaves a film that I like to wash off. See here for more details on how I polish silver.

Files

A set of high quality needle files along with a few flat files of various fineness will serve you well for various tasks. The more shapes and sizes you have the better. Available from a variety of sources- I like looking for old small files at yard sales, if they are a little worn out I find that actually can sometimes be a positive. One essential file is the screw slotting file available from various sources including Allied and often also gunsmithing supply places like Brownell’s.

A key bending pliers

As silly as it seems to have a particular pair of pliers that only really do one job (though every once in a while you’ll find another use, like the E key on an old horn with an forked Eb), it is worth it. These pliers adjust the height and attitude of the A key arm so that you can adjust it to act in sync with the C# and the bis. Available from Allied Supply as the “Stuvel Sax Key Adjusting Plier”.

Small parts containers

For holding small parts of a disassembled saxophone, like rollers and neck screw etc. I like to use old Altoid tins. Anything similar will do the job.

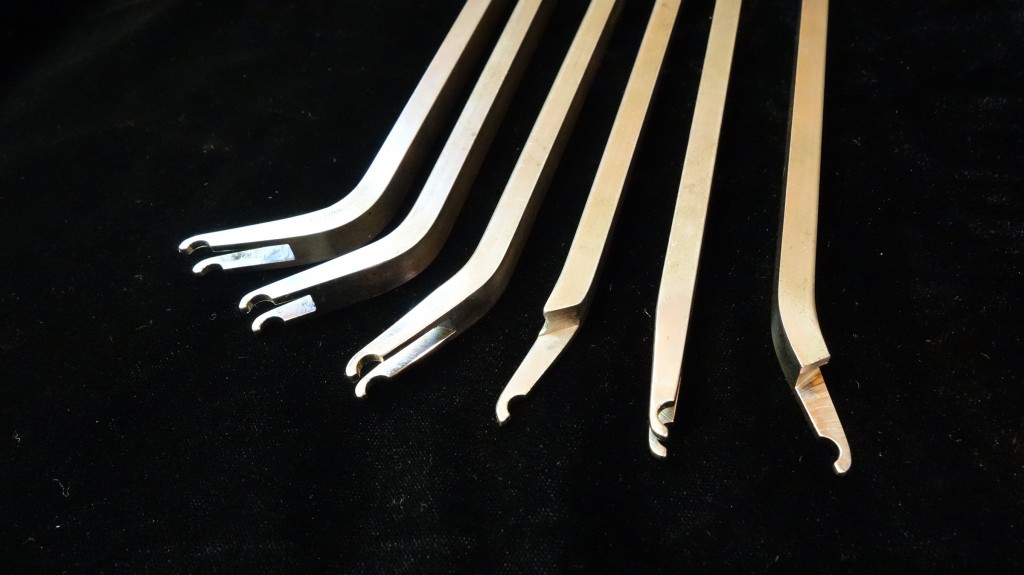

Key bending arms

Used with care to level and align the keycup over the tonehole prior to pad seating. Available from Ferree’s and Votaw, though the Ferree’s set is far more complete and is the one I recommend.

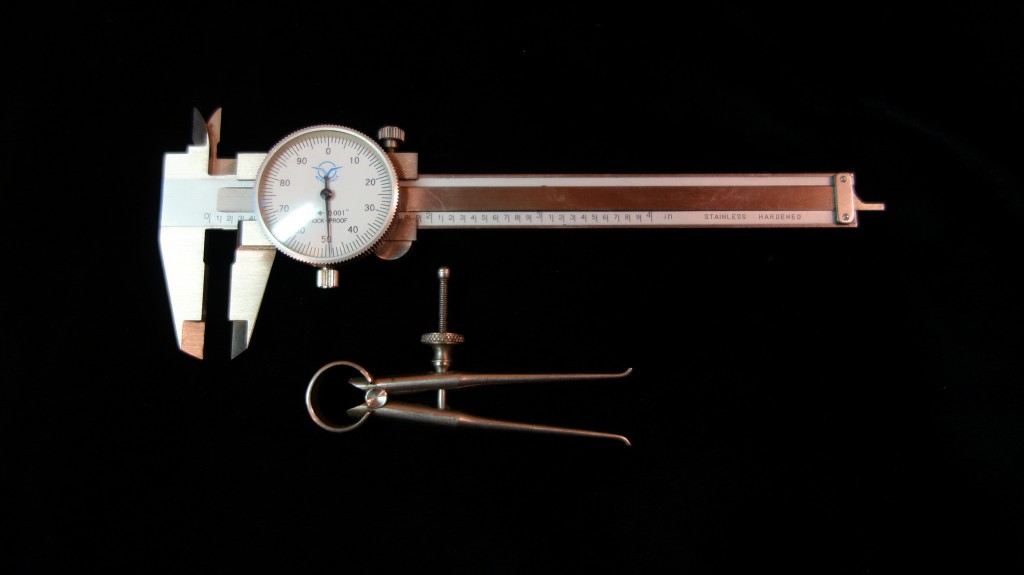

Calipers

You’ll want to measure things from time to time (key heights, for example), and a few decent calipers will do the job.

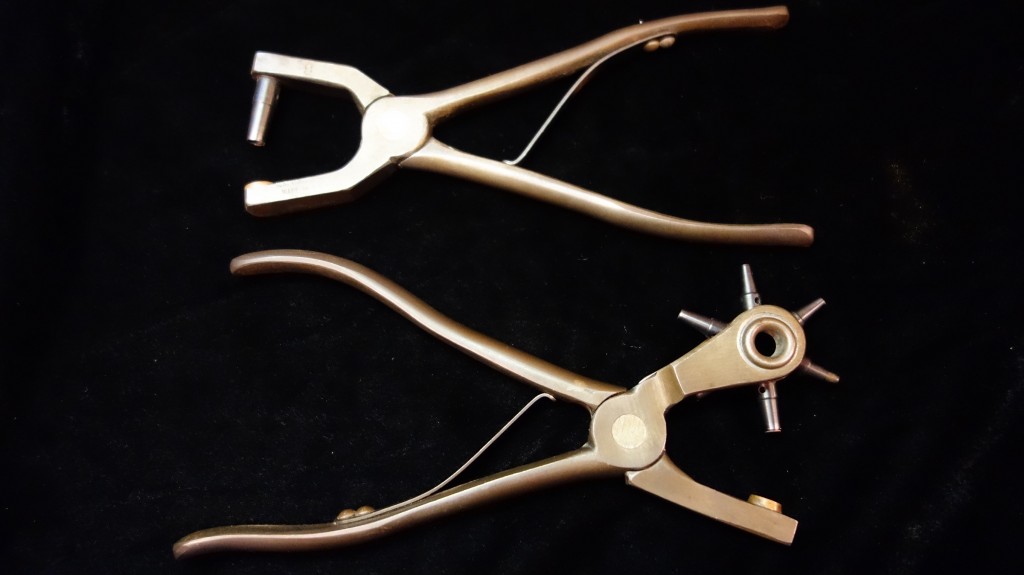

High quality hole punches

The kind used for leatherworking. You’ll want lots of different sizes of punch. In addition to the two punches seen here, I have about a dozen other sizes of standalone punch that I use with a punch block and hammer. You’ll use this for punching out pieces of adjustment material, so you want high quality and sharp, otherwise your work will look sloppy even if its functional. Don’t get cheap ones! You’ll just be buying them twice. Available from Ferree’s and elsewhere, the maker of the ones above is C.S. Osborne.

The Open Source Saxophone Project is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.